Fagor Automation is pleased to announce that all items in their renewed QUERCUS catalog are now available in the EPLAN Data Portal. The goal with this initiative is to make it easier for valued customers to seamlessly integrate Fagor Automation’s products into their electrical designs.

By publishing articles in the EPLAN Data Portal, Fagor Automation provides engineers and designers with easy and direct access to accurate and up-to-date data, improving efficiency in electrical designs and making component selection easier.

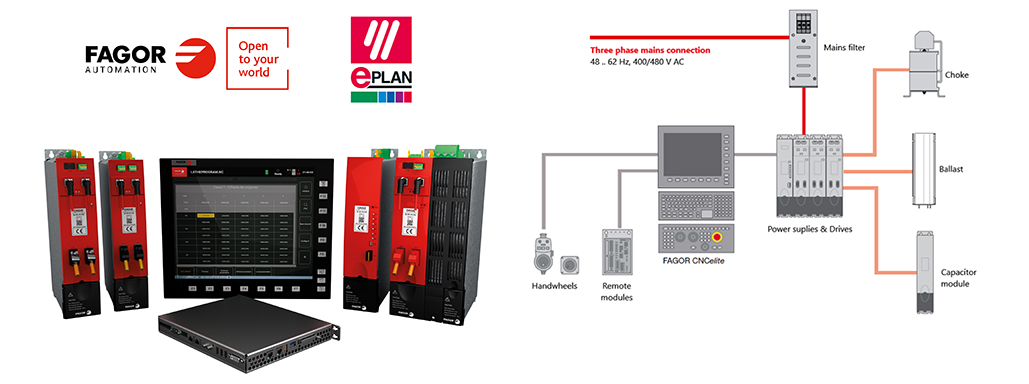

Fagor Automation has published the data of their QUERCUS CNC Automation system in the EPLAN Data Portal, offering a completely integrated solution and providing a wide range of references for both Converters and PLCs.

Fagor Automation has published the data of their QUERCUS CNC Automation system in the EPLAN Data Portal, offering a completely integrated solution and providing a wide range of references for both Converters and PLCs.

From the EPLAN Data Portal interface, users can filter items by entering “Fagor Automation” in the search box. Within EPLAN, Fagor Automation is identified by the acronym “FAU” as a component manufacturer.

For each component, you have access to the most complete and useful information, such as 2D, 3D and logic macros; connection and drilling patterns; function templates. Most importantly, they all meet the requirements of the EPLAN Data Standard!

Choosing EPLAN for electrical design can provide several advantages to a system manufacturer such as:

- Efficiency in Design: EPLAN offers tools that automate and streamline the electrical design process, resulting in greater efficiency in creating electrical schematics, circuit diagrams, and associated documentation.

- Accuracy and Error Reduction: Automation and consistency in design help reduce the possibility of human errors. The automatic generation of bills of materials (BOMs) and coherence checks in electrical schematics contribute to improved accuracy.

- Enhanced Collaboration: EPLAN facilitates collaboration between different teams within a project. Multiple users can work simultaneously on a design, and centralizing information on a platform can improve communication between design and manufacturing teams.

- Integration with Automation Tools: EPLAN can integrate with automation and manufacturing systems, allowing for a smoother transition from design to production. This is crucial for efficiency and consistency in the production chain.

- Detailed Technical Documentation: EPLAN automatically generates detailed technical documentation, facilitating the manufacturing, installation, and maintenance processes. This is valuable for ensuring consistency in the implementation of designs.

- Adaptability to Industry Standards: EPLAN is compatible with various industrial standards and regulations, making it easier for manufacturers to comply with specific industry requirements and ensure conformity in their electrical designs.

- Access to the Component Database: The ability to access EPLAN’s Component Database (Data Portal) makes it easier to select and use standard electrical components, saving time and ensuring the availability of accurate data.

In summary, the adoption of EPLAN by a systems manufacturer can improve operational efficiency, reduce costs associated with design errors, facilitate collaboration, and provide greater consistency in technical documentation, contributing to the overall quality of products and projects.